Wuxi Fenigal Science & Technology Co., Ltd

Manufacturer and Supplier for Industrial & Lighting Products

Wuxi Fenigal Science & Technology Co., Ltd

Manufacturer and Supplier for Industrial & Lighting Products

| Place of Origin: | China |

| Brand Name: | IONPURE |

| Certification: | CE |

| Model Number: | LX-Z |

| Minimum Order Quantity: | 1 pc |

|---|---|

| Price: | Negotiable |

| Packaging Details: | standard export packing |

| Delivery Time: | 5- 8 work days |

| Payment Terms: | Western Union, T/T |

| Supply Ability: | 60000 Unit/Units per Month |

| Features: | Fireproof, Waterproof | External Size: | 230*381*110mm |

|---|---|---|---|

| Customization Options: | Yes | Material: | Nylon Or PVC |

| Lamp Base: | G38 | Compatible Wire Size: | 12-14 AWG |

| Sodium: | ≤ 3 Ppb | Lock: | Available On Request |

| Amperage: | 0–5.2 ADC | Payment: | T/T,L/C,Western Union |

| Scalability: | Yes | Paint Finish: | Epoxy Polyester Coating |

| Product Type: | Electronic Data Interchange (EDI) Software | Certifications: | CE, RoHS |

| Way: | 12,16, 18, 20,24,36 | ||

| Highlight: | IONPURE® LX-Z CEDI Modules,water treatment solutions CEDI Modules,Industrial deionized water CEDI Modules |

||

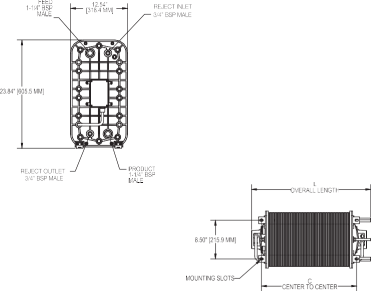

IONPURE LX-Z—a continuous electrode deionization (CEDI) module designed for industrial applications, has excellent chlorine tolerance and is widely used in various industrial deionized water application scenarios and markets, such as power plant boiler feed water, hydrocarbon and chemical process water (HPI/CPI) and other high-purity water needs. Compared with traditional deionization methods, IONPURE CEDI modules can continuously provide high-purity water flow without shutdown or chemical regeneration, bringing revolutionary water treatment solutions to the industrial field.

CE mark certification, each module is strictly tested before leaving the factory to meet the high standards of the industry and is manufactured under the conditions of complying with ISO 9001 and ISO 14000 quality and environmental management system standards.

IONPURE LX-Z module has the following significant advantages:

* Wide flow range, single module flow rate from 0.22 cubic meters/hour (1 gallon/minute) to 10 cubic meters/hour (44 gallons/minute), meeting the needs of various application scenarios.

* Significantly lower operating costs compared to traditional ion exchange methods.

* No need to use chemicals to generate mixed-bed quality deionized water.

* Achieve continuous production rather than batch processing to ensure stable and reliable water quality.

* Adopt double O-ring sealing design to ensure leak-free operation.

* No acid, base, neutralization system or replaceable deionized water tank required.

* Filled with premium resin for optimal performance and ease of operation.

* Support continuous operation to ensure uninterrupted water supply.

* Can handle incoming water up to 0.05ppm (total chloride ion content).

* The material of wet parts complies with NSF® 14 and NSF® 61 standards, which is safe and reliable.

About the operating environment of the IONPURE LX-Z module:

The module should be installed indoors, away from direct sunlight, and ensure that the ambient temperature does not exceed 113°F (45°C) to ensure its stable and efficient operation. This can effectively extend the service life of the module while ensuring the stability and reliability of the water quality.

* Actual performance can be accurately estimated using the IP-Pro prediction tool provided by Ionpure.

*Performance data is based on testing at the maximum inlet water conductivity equivalent value (40 μS/cm), ensuring excellent deionization results in various application scenarios.

E-Cell EDI Technology Performance Examples

![]()

E-Cell EDI technology has been successfully applied in various industries such as power, petroleum, chemical, steel, pharmaceutical, and electronics.

![]()

For application cases, please click:https://www.fgwater.com/Industries/

![]()

About Us

FG Water Technologies (www.fgwater.com) is now an organic part of Wuxi Fenigal Science and Technology Co. Ltd., which is a high-tech entity integrating water treatment quipment design, manufacturing, trading and shipment served for main industrial sectors.

HAFE-FG Water Technologies has focused on the research of water treatment technology, equipment development and manufacturing, testing and international shipment etc. We work with many leading large-scale or small-medium original equipment manufacturers in China High-tech Development Zones, and engaged ourselves in R&D, manufacturing, and quality testing.

Our main products include a variety of water purification and different treatment equipment, such as seawater reverse osmosis (SWRO) system, brackish water rever osmosis (BWRO), ultrafiltration (UF)system, Electrodeionization/EDI equipment, media pressure filters and ion exchanger softeners. So far, our company has become a major water treatment equipment supplier for food and beverage industry, pharmaceutical industry, chemical industry, electric power industry, urban water supply industry, municipal and industrial wastewater treatment and more industries, as well as being an exporter to more than 20 countries and regions in Asia, Europe, the Americas, Africa, etc.

![]()

Our production system consist of a list of industry-specialized partnership factories accross China. Some of them singularly cover an area of over 10,000 square meters, including 5,000 square meters of workshop and warehouse and 1,500 square meters of office buildings. All of our technical staff has more than 10 years of experience in the design of water treatment systems, so we are able to provide the perfect solution for all kinds of water purification and sewage treatment applications.

Since the establishment, the Company has always regarded quality as the life of our business. We choose the best components only for the production of various water treatment systems. Our systems are easy to use and maintain, and they stays highly reliable even under toughest conditions.

Contact Person: Mr. Harry

Tel: +86-13646187144